top of page

Latest News

We exhibited the panel on"Ultra-low dielectric loss SSBS and CCL for 5G"

at the Electronics 2024 Total Solution Exhibition (June 17, 2024)

At the Electronics 2024 Total Solution Exhibition held from June 12th to 14th, 2024,

we exhibited the panel about our "Ultra Low-Dielectric Loss SSBS and CCL for Beyond 5G"

at the JSR Corporation booth.

Click here for details on the exhibition panels

The article about our "Ultra-low CTE bonding sheet" was published in the Electronic Device Industry Newspaper (May 8, 2025)

Circuit Materials develops ultra-low CTE material for glass core substrates

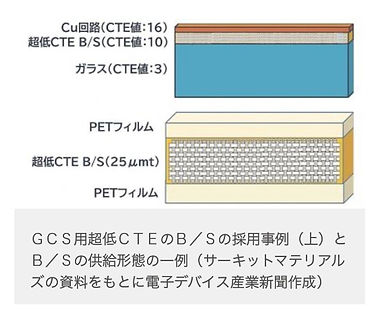

Circuit Materials INC. (Aoba-ku, Yokohama), which develops materials and provides consulting services for circuit substrates such as high-frequency compatible components, has developed an ultra-low CTE bonding sheet (BC) for glass core substrates (GCS). It will be proposed to domestic and overseas CCL (copper clad laminate) and package substrate manufacturers. It is also being developed for new applications, as it is believed that it may be used as an insulating material when laminating HBM, the demand for which is rapidly increasing for AI chips.

When manufacturing high-performance package substrates using glass core substrates, when copper circuits are formed directly on the glass, the difference in the CTE (coefficient of thermal expansion) values between glass and copper can be a major problem, and it is generally pointed out that this may impair processing and mounting reliability. Therefore, in order to mitigate the difference in the CTE values of glass (CTE value of about 3) and copper (CTE value of about 16), the company has developed a bonding sheet material with an ultra-low thermal expansion coefficient of about 10 and low dielectric properties (Dk 2.55/Df 0.0013). Since it does not contain silica or glass cloth, it is also excellent in laser processing for via formation. It can be made as thin as 1.5 μm. The peel strength is 0.70 N/mm and the water absorption rate is 0.05%, which is said to be no problem in actual use. These electrical properties have been improved by using special cloth, etc. The base resin of the ultra-low CTE bonding sheet developed this time is the new low-dielectric polymer "CM-937 series" designed by the company. The composition was designed and developed independently by Circuit Materials, and the new polymer has excellent low dielectric properties and excellent electrical properties with a water absorption rate of 0.2%. Its flame retardancy is equivalent to V-0, and its oxidation resistance has been proven to be significantly lower than that of PPE (polyphenylene ether). It also overcomes the problems of low Df/Dk and adhesion strength, which are often trade-offs.

The new polymer material also has an adhesive function, so it boasts high bonding strength (peel strength is 0.82 N/mm) with metals and other metallic materials and different materials. This eliminates the need for roughening the copper foil surface, and it also has excellent high-frequency characteristics. Even when processed into a bonding sheet with an ultra-low CTE, it has a CTE of about 0.7 N/mm, so there are no problems in actual use.

When used as a bonding sheet, it is ideal for SAP and MSAP methods, which allow for the formation of fine wiring. It is also proposed for use as RCC (resin-coated copper foil) in the conventional subtractive method.

bottom of page